Recent anti-encroachment drive of Mysore is an example of admirable planning and execution. The drive was directed and managed by the MCC commissioner K. S Raykar.

Planning Phase:Almost 6 months

a) to get approvals from higher ups including district minister Shobha Karandlaje

b) to develop project execution plan.

Departments Involved: MCC, MUDA, Mysore Police (KSRP, CAR, DAR...etc), Telecom Department

Project Leads: K.S Raykar( MCC Commissioner), Manivannan (DCP), Sunil Agarwal (Police Commissioner)

Project Team Structure/Resourcing:

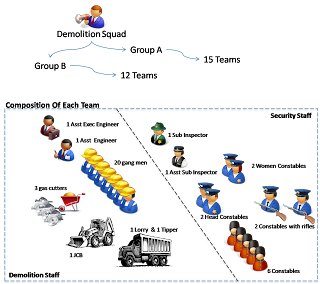

Commanded by: 2 teams of MUDA and MCC

Executed By: 27 teams of workers!!!

The team organization and composition of each team is shown below.

Risks/ Risk Mitigation:

Stay Order from Court: The operation was started on a Sunday, early in the morning - no court is open at that time.

Influence from elected representatives: All the phone lines, land line and mobile, were jammed with help of Telecom providers - physical presence required for any kind of influence.

People gathering to protest: Jamming of phone lines prevent mobilization of people. Also, 500 policemen providing security would deter anyone raising voice.

Result: More than 450 encroachments cleared by noon!

Issues Encountered: There was protest by the elected representatives at the demolition site. The threat of arrest, and few arrests, by the police was enough to diffuse the crowd.

Post Execution: MCC Commissioner goes on a 3 day sick leave from Monday – leaving all the encroachers and their supporters with the rubble!